New Zebra study shows nearly half of Asia-Pacific manufacturers to have smart factories by 2022

Zebra Technologies released the results of the Zebra’s 2017 Asia Pacific Manufacturing Vision Study, a body of research analyzing the emerging trends shaping the future of industrial manufacturing. To help manufacturers meet the growing demand and increase operational visibility, Zebra is introducing its new ZT600- and ZT510-series industrial printers designed to withstand the harshest environments while delivering superior print quality and uptime.

The next-generation ZT610 and ZT620 maintain Zebra’s legacy of producing durable, reliable printers with fast print speeds that increase productivity in the retail, manufacturing, transportation and logistics and healthcare industries.

Building on the success of the Xi4 series, the ZT600 printer series offers new user-friendly features like simplified media and ribbon loading, a highly visible color display that shares printer status, and guided multi-media help that indicate errors to help users resolve issues quickly and increase printer uptime.

The ZT600 series runs Link-OS applications designed to streamline device deployment, network connectivity, daily use, and routine maintenance to optimize productivity. Printer Profile Manager Enterprise enables IT staff to maintain Link-OS-enabled printers with the most up-to-date security and makes it easy to remotely manage, troubleshoot and configure fleets of Zebra printers from a single location, reducing operational expenses.

Zebra is also introducing the cost-effective ZT510 printer, ideal for applications that require a basic feature set, yet exceed expectations of high-quality printing and durability. Zebra printers work best with Zebra Certified Supplies, including thermal labels, tags and stock RFID identifiers, are available to help ensure consistency, while lowering total cost of ownership and optimizing printer performance.

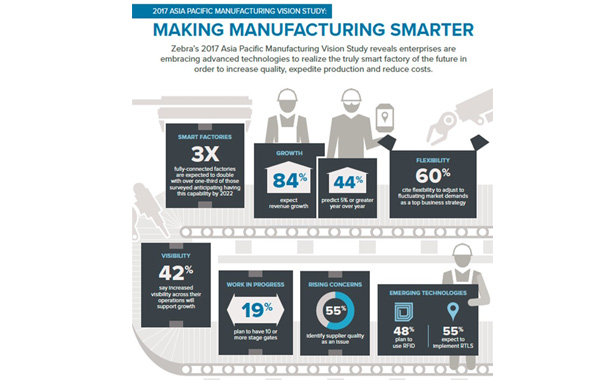

Also, below are the key findings from Zebra’s 2017 APAC Manufacturing Vision Study.

KEY SURVEY FINDINGS

- The regional study discovered that the number of manufacturers supporting a fully connected factory would nearly triple by 2022. This means 46 percent anticipate having the capability in five years’ time.

- Manufacturers will continue to adopt Industry 4.0 and the smart factory. Workers will use a combination of radio frequency identification (RFID), wearable technologies, automated systems and other emerging technologies to monitor the physical processes of the plant and enable companies to make decentralized decisions. APAC manufacturers will lead the way globally, with 77 percent of respondents expecting to collect data from production, supply chain, and workers in a holistic manner by 2020, compared to 46 percent doing so today.

- Executives across APAC cited achieving quality assurance as their top priority over the next five years. Forward-looking manufacturers are embracing a quality-minded philosophy to drive growth, throughput and profitability. In a sign that improvements made by both suppliers and manufacturers will ultimately boost the quality of finished goods, fewer respondents say quality-related issues will be a top concern in the future. Today, 55 percent of manufacturers see quality as a top concern, but this falls to 35 percent in 2022.

- Manufacturers expect to expand the level of technology use between now and 2022, specifically mobile technology (27 percent vs 72 percent), wearable technology (33 percent vs 65 percent), location tracking (38 percent vs 51 percent), and voice technology (45 percent vs 51 percent).

- Forty-two percent of the manufacturers expect investments in visibility technology to spur growth. Fifty-five percent will implement real-time location systems (RTLS) and 48 percent plan to use RFID by 2022, providing the much-needed transparency across their operations.

- By 2022, 44 percent of manufacturers expect to enable Just-In-Time (JIT) notifications for their customers. The request will increasingly come from the high-tech (48 percent), pharmaceutical (40 percent), automotive (35 percent), and food & beverage (36 percent) industries.

Deep Agarwal, Regional Sales Director – India, Zebra Technologies APAC said, “Manufacturers are entering a new era where there are increasing expectations of faster and higher quality production along with highly competitive margins. India is at the forefront of a digital revolution, with the potential to become the digital factory of the world. The Zebra APAC Manufacturing Vision Study shows savvy manufacturers have already started to invest in smart factory technologies to reap benefits such as enhanced productivity, increased visibility, and the ability to predict demands. As we move toward Industry 4.0, this trend will continue to expand and shape the industry in the coming years.”

Jason Low, APAC Lead for Specialty Printing Group, Zebra Technologies, Asia Pacific said, “Industrial printers play an essential role in a highly efficient supply chain, allowing enterprises to track every single component or asset from assembly to delivery and aftersales service. The ZT600 and ZT500 series printers provide unparalleled quality, durability, and performance that can withstand any tough environments. Coupled with our Link-OS and the Printer Profile Manager Enterprise, Zebra is making printers easier to network, use, deploy, maintain, and troubleshoot, ultimately improving productivity and operational efficiency.”