Honeywell UOP introduced its new Connected Plant ARMGuard system, a remote monitoring service that helps natural gas processors manage the adsorbents that are used to remove water from natural gas.

Honeywell UOP’s ARMGuard system uses existing instrumentation to help customers optimize their adsorption cycles, reduce energy consumption, operate under variable feed conditions, and reduce costs due to unscheduled shutdowns.

Natural gas at the wellhead naturally contains water and water vapor that, if left in the natural gas stream, will freeze as the gas is being cooled into a liquid, clogging the lines with ice. This water can be removed with adsorbents, which trap the water molecules before the gas is cooled. Most adsorbent systems are not actively monitored and analyzed for optimal performance, causing these systems to run well below their capability, wasting energy and underutilizing the adsorbent.

“The ARMGuard system monitors the performance of our adsorbents to advise how the dehydration process can be kept running efficiently and reliably,” said Ken Stacherski, vice president and general manager of Catalysts, Adsorbents, and Specialties at Honeywell UOP. “The more effectively you can manage your adsorption system, the more effectively you can keep the unit on-stream and operating profitability.”

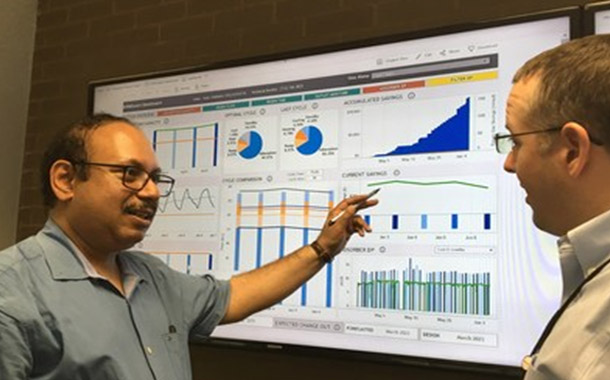

Honeywell UOP’s ARMGuard system, which entered service in May with Enterprise Products in Opal, Wyo., continuously collects operating data from the adsorbent unit and analyzes it using UOP adsorbent models to determine the effectiveness of the process. The system can detect issues that, with the assistance of UOP’s technical team, can be used to improve unit performance and prolong adsorbent life.

“Nothing like this has ever existed before because it’s a software-based service dedicated specifically to dehydration, and it compares plant operation to proprietary UOP process models,” Stacherski said. “As a result, these models reference the true capability of the adsorbent, not just the past operation of a plant.”

In addition, the ARMGuard system can detect process upsets and recommend ideal adsorbent regeneration cycles to increase adsorbent performance and reduce operational costs. It also can forecast optimal adsorbent change out times to better plan maintenance downtime.

The ARMGuard system can be connected to a customer’s corporate data historian, which aggregates the operation of several gas plants at once. Once established, the system can help to reduce energy consumption by as much as 20 percent and increase the useful life of an adsorbent, also by 20 percent.